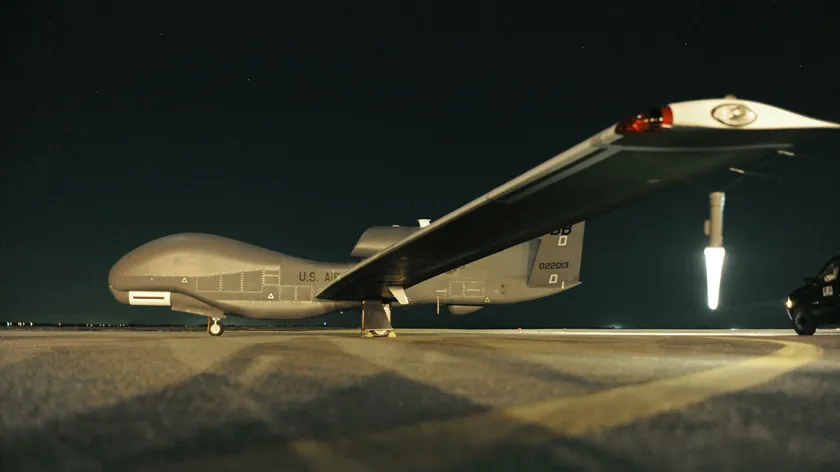

On August 20, 2011, the US military investigated the crash of a Global Hawk RQ-4 Air Force Drone outside Kandahar, Afghanistan. The report concluded that the cause of the crash was a mis-tightened bolt. This cost them a total of 74 million USD.

On August 20, 2011, the US military investigated the crash of the Global Hawk RQ-4 Air Force Drone outside Kandahar, Afghanistan. The report concluded that the cause of the crash was improperly tightened cylinder screws. This cost them a total of 74 million USD.

Torque tools are precision tools used to tighten fasteners with a specific torque, such as bolts and nuts. The correct torque is important to prevent parts from loosening and to ensure that gaskets are tight. Too much torque can cause bolts or threads to be damaged, or bolts to become impossible to loosen.

Tightening bolts can be done in several ways. The most common method is tightening using a calibrated torque wrench. The required torque in the wrench is calculated from the desired preload force in the bolt. Angular rotation of the bolts is another tightening method, and this can also be combined with the use of a torque wrench. A final method is the use of a hydraulic preload tool. The preload force in the bolts can be reduced over time and the reasons for this can be overload or fatigue loads.

In order for the bolted connections to be able to withstand static and dynamic loads over time, the bolts must be fastened with a certain preload. Lack of preload can give dynamic loads that can result in fatigue of the bolts. The required preload force depends on the quality and surface treatment of the bolts, as well as the friction between the bolt/nut and between the nut/base material.

The preload force should not exceed the yield point of the bolts. Preload of bolts can be carried out in different ways:

Tensioning using a calibrated torque wrench

Tensioning by rotation of the nut (turn-of-the-nut)

Combined method

Using a calibrated torque wrench, the relationship between preload force and torque in the wrench is exploited. The torque wrench is calibrated so that it “releases” when the correct torque is achieved. This torque is calculated from the desired preload in the bolt.

The “turn-of-the-nut” method tightens the nut so that it is “tight”. The surfaces of the base material should then be pressed together. The nut should then be turned a certain angle to ensure the correct preload in the bolt. This angle depends on the bolt diameter, thread type and clamping length. The last method is a combination of torque tightening and nut turning. The bolt is first tightened with a torque equivalent to 75% of the desired preload force, and then the nut is turned 90 degrees.

The report to the US military concluded that the RQ-4 drone had Allen screws that had not been tightened to torque specifications, which resulted in the cylinder screws with internal hexagons loosening during flight.

Correct torque and safety when preloading bolts is not only important when manufacturing drones worth several million kroner. This applies to several industries that rely on torque tools to perform work.

kNm Hydraulics offers a range of bolt preload products from Enerpac and Gedore – click on one of the links below to find out more about these products:

Here you can see the drone before the accident and after it crashed. Here you can really see what a wrongly tightened bolt can do and how much it can actually cost a company when someone tightens a bolt with too much or too little torque.