There are several different elements that determine whether a new flange connection will be both secure and leak-free. One of the most important elements in ensuring this is the bolt tightening sequence.

For a new bolt driver, this may seem very easy to figure out. What often happens is that you just assume you are applying full torque to the first bolt and then move the tool to the next. This is the wrong approach – the order in which you tighten the bolts and the load have a huge effect on the integrity of the joint.

ATTRACTION SEQUENCE – WHY IS IT SO IMPORTANT?

To complete work on a flange connection safely, it is very important to control the tension variations. In the case of the gasket, it must be compressed evenly across the flange face. Tightening the nearest bolts when the opposite bolts are loose will result in uneven compression, and damage to the gasket.

The flange must be tightened very slowly and parallel. In practice, this means starting with the correct bolt tightening pattern at part load and then performing more, increasing the load each time.

The ASME (American Society of Mechanical Engineers) PCC-1-2019 standard is the “go-to” document for bolting standards. PCC-1-2019 provides several options for different sequences that can be followed for a leak-free flange.

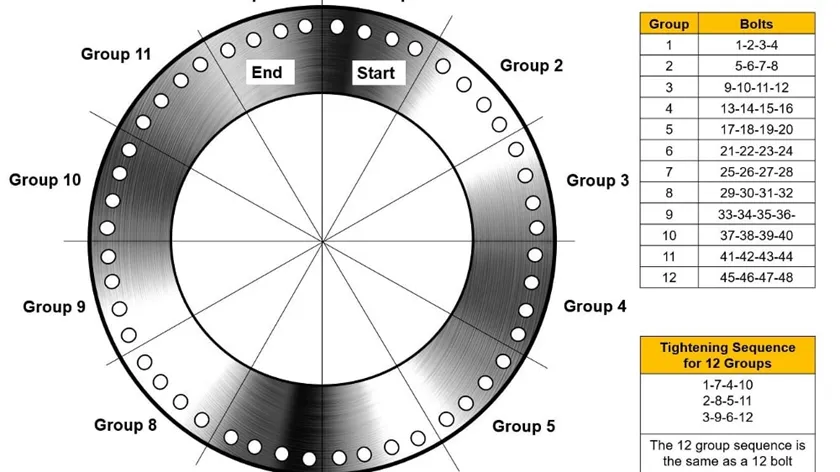

Before tightening the bolts, they are numbered sequentially (1, 2, 3, 4, etc.) clockwise around the flange (Fig.1)

They can also be numbered by order of tightening (fig.2). Both methods have their advantages, but what is important is that what is chosen is agreed in advance and that the crew has enough knowledge and experience to carry out the job.

For very large flanges (48-bolt) the process may be different. Here, groups of 4 bolts can be treated as 1 bolt – resulting in 12 groups. For example – tighten 1, 2, 3 and 4 before moving on to group 7. ASME recommends that possible gasket damage or flange misalignment should be considered when bolts are grouped.

SUMMARY

For a newbie this can seem very overwhelming. However, following the correct procedures and taking the extra time needed will help to avoid potentially dangerous and time-consuming maintenance in the future. Using a well-designed hydraulic torque wrench will make the process efficient and trouble-free.